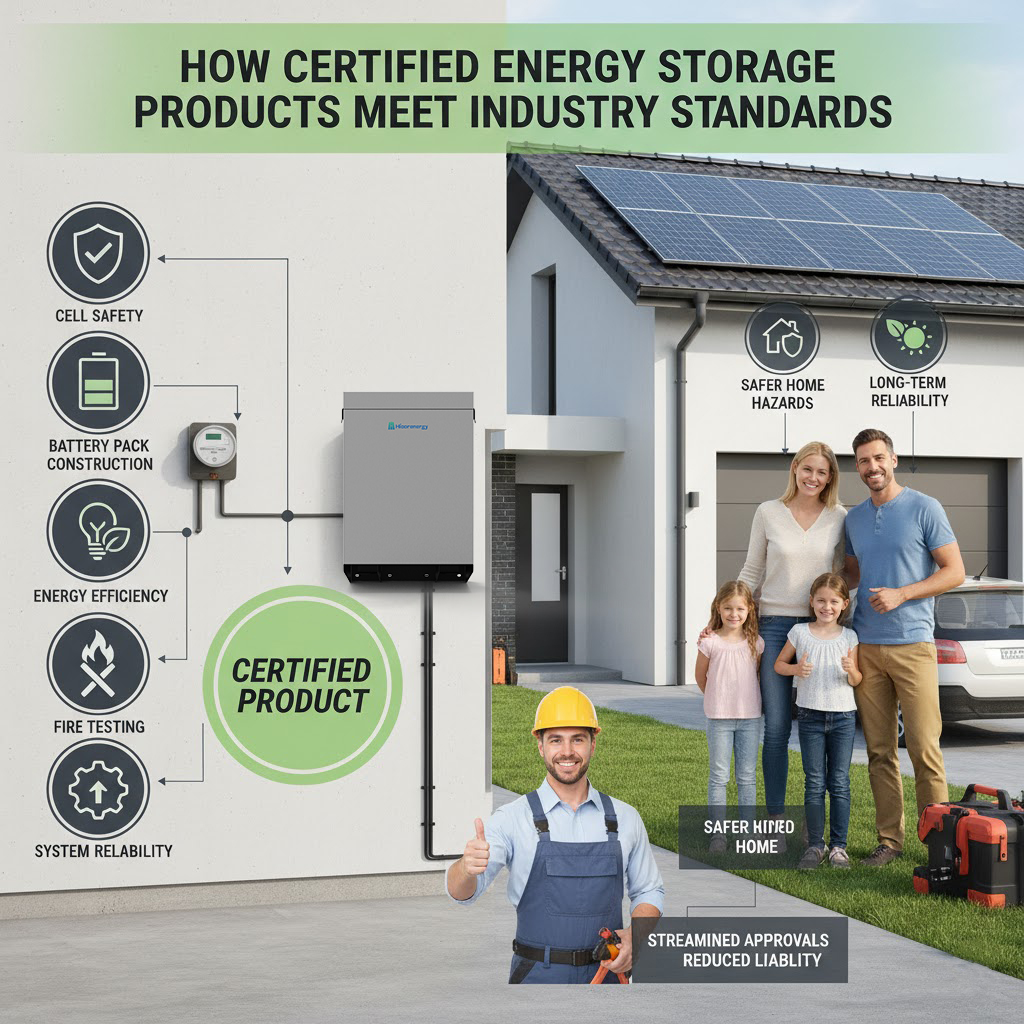

Battery System Safety Certification ensures that energy storage products meet strict safety, performance, and reliability requirements. For distributors and installers, certified systems reduce operational risk, simplify permitting, and guarantee product quality—making compliance essential for market access and long-term customer trust.

What is Battery System Safety Certification and Why It Matters

Battery System Safety Certification refers to a structured evaluation process designed to confirm that an energy storage system meets defined safety and performance benchmarks. It matters because certified battery systems reduce hazards such as thermal runaway, electrical failure, and installation risks, ensuring safer deployment in residential, commercial, and industrial environments.

Overview of Key Battery Safety Standards and Certifications

An overview of key battery safety standards and certifications reveals a wide ecosystem that guides global market compliance. Certifications such as UL 9540, UL 9540A, IEC 62619, IEC 62133, UN38.3, and ISO safety frameworks evaluate batteries from cell level to full system operation. These standards cover electrical protection, thermal behavior, transportation safety, and operational performance. For example, UL 9540A tests thermal runaway propagation, while IEC 62619 focuses on industrial lithium battery safety. International markets require different combinations of these certifications, and manufacturers serving global distributors must meet multiple regulatory expectations. Leading suppliers such as Hicorenergy consistently align products with these benchmarks to support compatibility with regional permitting, utility integration, and safety compliance requirements.

Ensuring compliance with safety regulations requires proper product selection, verified test documentation, and installation procedures that follow local codes. Distributors and installers should always examine third-party test reports, verify certification scope, and confirm that system design and operating conditions match local regulation and utility requirements.

The Role of Certifications in Ensuring Battery Performance and Reliability

Battery System Safety Certification plays an essential role in guaranteeing long-term system durability, stable performance, and operational safety. Certified systems offer verified protection features such as over-current protection, thermal controls, and cell-level balancing—reducing service costs and failure risks. Hicorenergy integrates these principles throughout its energy storage portfolio. Residential products such as the I-BOX 48100R and C5° incorporate Tier 1 LiFePO4 cells, dual-MCU BMS architecture, wide-temperature operation, and thousands of certified cycles to ensure stable performance. The Si LV1 system, backed by UL 9540A large-scale testing and built-in DC protection, accelerates permitting and strengthens reliability in residential applications. For commercial and industrial systems, the SHV48100 cabinet and Si Station series follow global grid compliance standards, ensuring robust performance in large-scale deployments. These certifications not only assure safety but also build confidence for distributors, installers, and end users relying on dependable energy storage.

Global Safety Standards for Energy Storage Systems

Global Battery System Safety Certification frameworks vary widely across regions, shaping how distributors and installers evaluate products. In North America, UL 9540 and UL 1741 dominate system and inverter compliance, supported by UL 9540A for thermal propagation assessment. Europe commonly applies IEC 62619, IEC 62933, and CE conformity requirements related to electrical safety and EMC testing. Asian and Middle Eastern markets may adopt a combination of local codes and internationally recognized standards. These safety expectations also extend to installation conditions—such as indoor/outdoor ratings, IP protection levels, fire resistance, and system scalability. As energy storage adoption expands, adherence to global standards becomes critical for product acceptance, utility interconnection, insurance approval, and project certification. Suppliers like Hicorenergy design systems with multi-region compliance in mind, enabling easier entry into markets such as Africa, Southeast Asia, North America, and the EU.

Steps to Obtain Battery System Safety Certification

Certification typically follows a structured multi-stage process. First, the manufacturer submits system documentation, structural schematics, and protective feature descriptions to an accredited testing laboratory. Second, samples undergo electrical, mechanical, and thermal testing based on standards such as IEC 62619 or UL 9540A. These tests evaluate stress tolerance, charging behavior, thermal control, and failure conditions. Third, the facility’s quality control system is audited to ensure production consistency. After passing all evaluations, the product receives certification marks and compliance reporting. Distributors and installers should always request authentic test reports, production audit records, and serial-number-based traceability to ensure the certification applies to the actual product model being supplied.

Summary

Hicorenergy’s certified residential and C&I energy storage systems deliver high safety, long service life, and strong global compliance, supporting reliable deployment for distributors and installers worldwide.

Contact: info@hicorpower.com | WhatsApp: +86 181-0666-3226