The Regulator’s Crucial Warning surrounding the Sigenergy Plug incident highlights serious safety, compliance, and supply chain risks in the energy storage sector. Melted plug failures triggered regulatory scrutiny, mandatory corrective actions, and renewed focus on installer responsibility. Distributors and installers must strengthen component vetting, installation standards, and brand selection to protect projects, reputations, and long-term growth.

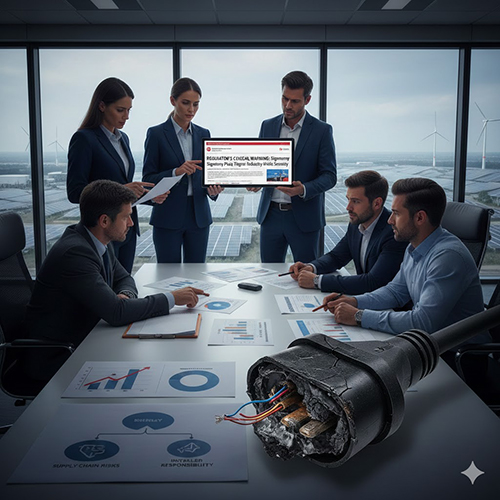

Incident Analysis: What Happened with the Sigenergy Melted Plugs?

The Sigenergy Plug incident emerged after reports of connector overheating and melting during operation in certain energy storage installations. Investigations suggest a combination of connector design limitations, installation stress, and real-world load conditions contributed to excessive heat buildup. While not all systems were affected, the visible damage raised immediate safety concerns, prompting regulatory review. The case underscores how seemingly minor components, such as plugs and connectors, can become critical failure points if not engineered, installed, and tested for long-term operating conditions.

Regulator's Key Findings and Mandatory Safety Directives

Following the Regulator’s Crucial Warning, authorities identified insufficient thermal tolerance and inadequate risk mitigation in affected Sigenergy Plug configurations. Regulators mandated inspections, corrective actions, and clearer installation guidance to prevent recurrence. According to safety and compliance insights referenced on hicorpower.com, regulators increasingly expect manufacturers and channel partners to demonstrate full component traceability, documented testing, and installer training alignment. These directives signal a broader regulatory shift: safety accountability now spans manufacturers, distributors, and installers—not just product designers.

Supply Chain Vigilance: How Distributors Can Mitigate Component Risk

For distributors, the Sigenergy Plug incident serves as a wake-up call. Component-level risk can cascade across entire portfolios if not proactively managed. Strong supply chain vigilance means auditing supplier certifications, requesting third-party test reports, and monitoring post-installation feedback from installers. Distributors should also diversify sourcing to avoid dependence on single-component designs. By acting early—before regulators intervene—distributors can shield partners from recalls, reduce warranty exposure, and reinforce trust during periods shaped by the Regulator’s Crucial Warning.

Installer Checklist: Verifying Product Compliance and Safe Installation Practices

Installers sit at the final—and most visible—link in the safety chain. In light of the Regulator’s Crucial Warning, installers must implement a rigorous pre-installation checklist. This includes verifying that all plugs, cables, and connectors match manufacturer specifications, checking torque and seating requirements, and ensuring adequate ventilation around high-current components. Documentation matters: keeping records of serial numbers, firmware versions, and installation photos can be critical if post-install inspections occur. Regular refresher training helps teams stay aligned with evolving safety standards and prevents shortcuts that could lead to failures similar to the Sigenergy Plug incident.

Beyond the Recall: Building Long-Term Trust in Energy Storage Brands

Recalls and safety incidents test brand credibility—but they also separate reactive suppliers from resilient ones. Long-term trust is built on conservative design, transparent testing, and installer-centric engineering. Hicorenergy products emphasize robust connector design, high thermal margins, and modular architectures that reduce stress on individual components. By prioritizing safety from the component level upward, brands can reassure distributors and installers seeking alternatives after incidents like the Sigenergy Plug failure. In a market shaped by the Regulator’s Crucial Warning, trust becomes a competitive advantage, not a marketing slogan.

Proactive Risk Management: Resources for Staying Ahead of Safety Standards

Energy storage regulations continue to evolve rapidly. Staying compliant requires more than reacting to warnings—it demands continuous education. Installers and distributors should follow regulatory bulletins, manufacturer technical updates, and independent testing bodies. Participating in manufacturer training programs and industry webinars ensures early awareness of potential risks. Internal audits, mock inspections, and periodic system reviews further reduce exposure. The lessons from the Sigenergy Plug incident show that proactive risk management is far less costly than corrective action after regulators step in.

Final Summary

The Regulator’s Crucial Warning highlights why component safety cannot be overlooked. With hicorenergy’s rigorously tested systems, robust connectors, and installer-focused design, partners can reduce risk, enhance compliance, and build confidence in every installation.

For product details and partnership support:

Email: info@hicorpower.com

WhatsApp: +86 181-0666-3226