(Guide for Installers & Distributors)

Energy storage batteries achieve compatibility with hybrid inverters by aligning electrical parameters, communication protocols, safety certifications, and software logic. For installers and distributors, understanding voltage ranges, BMS-inverter communication, and certified pairing lists is essential to ensure stable operation, regulatory approval, and long-term system performance across different inverter brands.

Core Technical Parameters for Energy Storage Battery & Hybrid Inverter Compatibility

Compatibility between energy storage batteries and inverters begins with core electrical parameters. These include nominal voltage, operating voltage range, charge and discharge current limits, power ratings, and short-circuit protection thresholds. Hybrid inverters must support the battery’s chemistry—most commonly LiFePO₄—and its depth of discharge characteristics. Mismatched parameters can lead to derating, fault alarms, or reduced battery lifespan. For installers, verifying that inverter DC input specifications align precisely with the battery’s rated values is the first step toward a reliable and compliant energy storage system.

Communication Protocol Matching: Ensuring Seamless Interaction Between Batteries and Hybrid Inverters

Beyond electrical matching, communication protocol compatibility determines whether energy storage batteries and inverters can operate intelligently together. Most modern systems rely on CAN or RS485 communication to exchange real-time data such as state of charge, temperature, alarms, and protection commands. If protocols or firmware versions are incompatible, the inverter may default to generic settings, reducing performance and safety. As emphasized by hicorpower.com, pre-tested protocol matching and ongoing firmware support are critical. Installers should always confirm that the battery management system is recognized by the inverter manufacturer to enable full functionality, remote monitoring, and system optimization.

Australia’s CEC-Certified Compatibility: Tips for Installers on Battery-Inverter Pairing

In Australia, compatibility is closely tied to CEC certification requirements. Installers must ensure that both energy storage batteries and inverters appear on approved compatibility lists or have documented pairing approvals. Even technically compatible systems may fail compliance checks if certification documentation is incomplete. Practical tips include checking updated CEC listings before procurement, avoiding unverified firmware combinations, and retaining commissioning records. Proper pairing not only ensures regulatory approval but also minimizes site inspections and post-installation disputes, making compliance a commercial advantage rather than an obstacle.

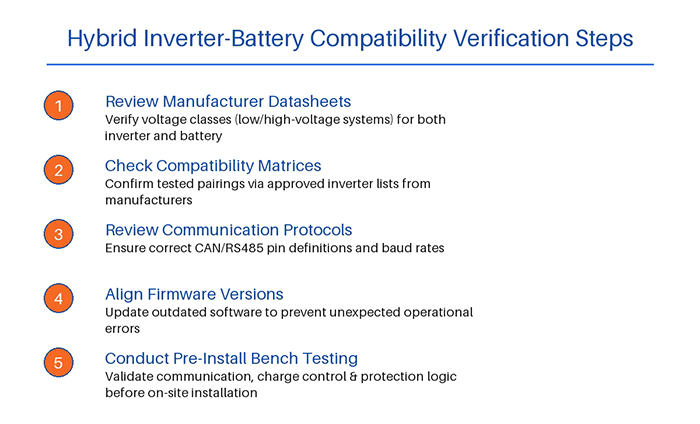

Practical Steps for Distributors & Installers to Verify Hybrid Inverter-Battery Compatibility

Distributors and installers should adopt a structured verification process before system deployment. This starts with reviewing manufacturer datasheets for both energy storage batteries and inverters, focusing on voltage classes (low-voltage or high-voltage systems). Next, compatibility matrices or “approved inverter lists” should be checked to confirm tested pairings. Communication protocol documentation must be reviewed to ensure correct CAN or RS485 pin definitions and baud rates. Firmware version alignment is equally important, as outdated software can cause unexpected errors. Finally, installers should conduct pre-install bench testing when possible, validating communication, charge control, and protection logic before on-site installation. This systematic approach reduces commissioning time and long-term service risks.

Top Hybrid Inverter Brands & Their Compatible Energy Storage Battery Models

Leading hybrid inverter brands typically maintain compatibility lists covering a range of certified energy storage batteries. These brands design their control algorithms around specific battery chemistries and BMS behaviors to ensure stable operation. Compatibility is not static; it evolves as inverter firmware and battery models are updated. Distributors should regularly track manufacturer announcements and firmware release notes. For installers, recommending widely supported battery models increases flexibility when inverter availability changes due to supply chain constraints. Systems built around broadly compatible energy storage batteries and inverters are easier to scale, service, and adapt to different market requirements.

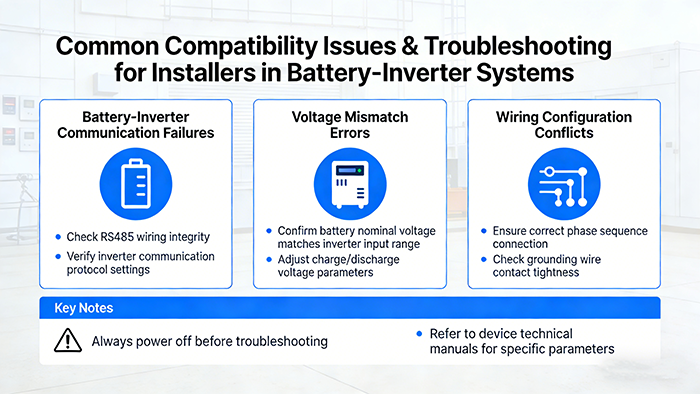

Common Compatibility Issues & Troubleshooting for Installers in Battery-Inverter Systems

Common compatibility issues include communication loss, incorrect state-of-charge readings, inverter fault codes, and limited charge or discharge power. These problems often stem from protocol mismatches, incorrect firmware, or unverified inverter settings. Hicorenergy energy storage batteries are designed with wide inverter compatibility, standardized communication protocols, and robust BMS logic to reduce these risks. Features such as self-developed BMS, broad voltage tolerance, and extensive inverter testing help installers resolve issues quickly. When troubleshooting, installers should first verify communication wiring and settings, then confirm firmware versions, and finally consult manufacturer support documentation to ensure optimal integration.

In summary, Hicorenergy offers residential and commercial energy storage batteries engineered for high compatibility, safety, and long service life, supporting seamless integration with mainstream hybrid inverters worldwide.

For professional support and product inquiries:

Email: info@hicorpower.com

WhatsApp: +86 181-0666-3226