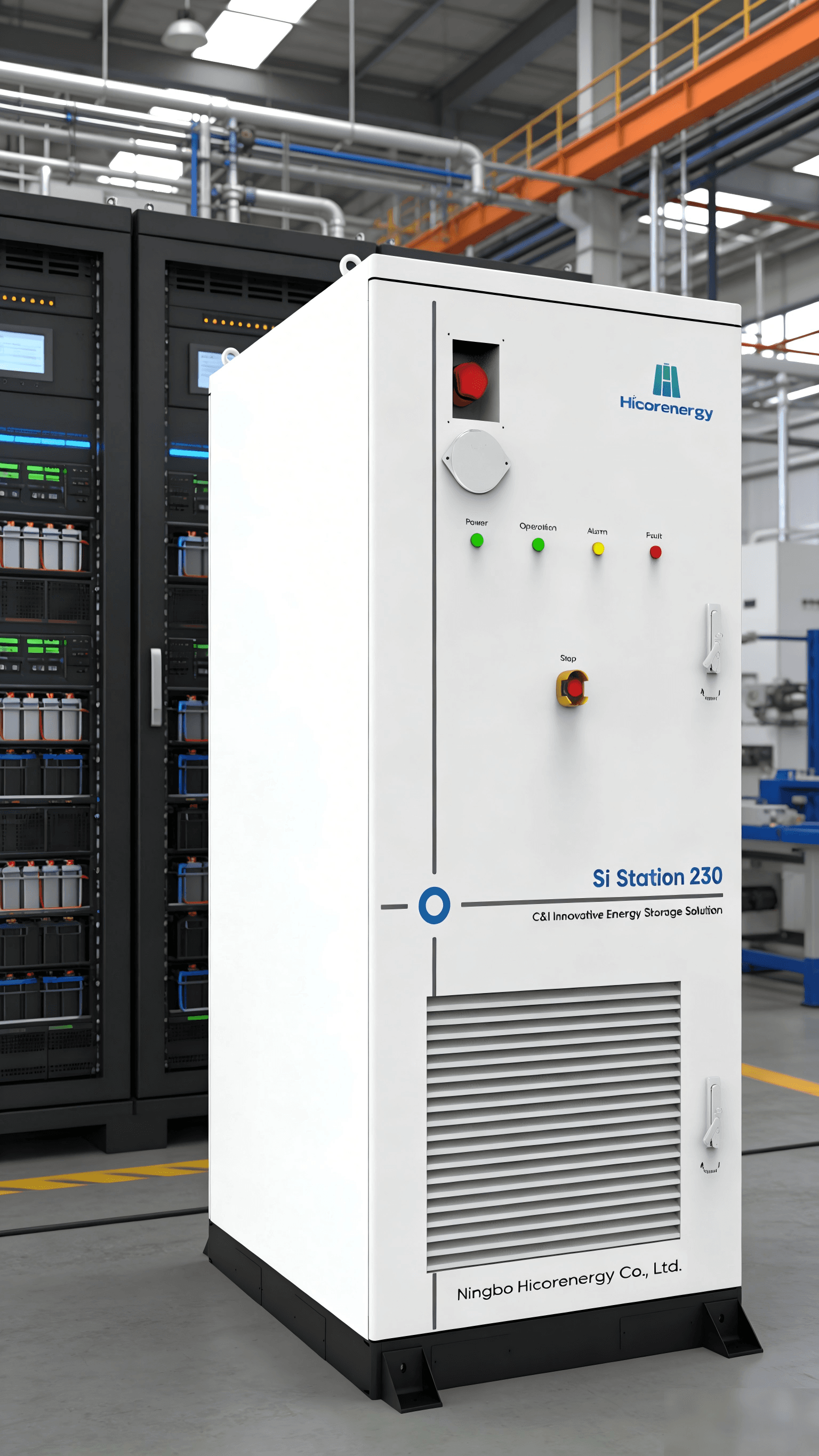

The performance, longevity, and safety of modern energy storage solutions are intrinsically linked to their ability to manage thermal loads effectively. For large-scale applications, particularly those integrating with renewable sources like solar and wind, maintaining optimal operating temperatures is paramount. This is where advanced Cooling systems for lithium ion batteries come into play, with air-based methods representing a robust, reliable, and widely adopted approach. An effective Air Cooling Battery System is not merely about blowing air over cells; it's a sophisticated engineering discipline crucial for unlocking the full potential of battery technology, ensuring both efficiency and safety in systems like Hicorenergy's state-of-the-art SI Station.

The performance, longevity, and safety of modern energy storage solutions are intrinsically linked to their ability to manage thermal loads effectively. For large-scale applications, particularly those integrating with renewable sources like solar and wind, maintaining optimal operating temperatures is paramount. This is where advanced Cooling systems for lithium ion batteries come into play, with air-based methods representing a robust, reliable, and widely adopted approach. An effective Air Cooling Battery System is not merely about blowing air over cells; it's a sophisticated engineering discipline crucial for unlocking the full potential of battery technology, ensuring both efficiency and safety in systems like Hicorenergy's state-of-the-art SI Station.

The Mechanics of an Air Cooling Battery System

At its core, an Air Cooling Battery System utilizes ambient or conditioned air as the primary medium for heat dissipation. The fundamental principle involves moving a high volume of air across the surface of battery cells or modules to carry away the waste heat generated during charge and discharge cycles. This is typically achieved using a combination of high-performance fans or blowers, strategically designed plenums, and intricate ductwork. The simplicity of this approach is one of its greatest strengths, reducing system complexity and maintenance requirements compared to liquid cooling alternatives. In advanced energy storage units, these systems are engineered for maximum thermal transfer, ensuring that every part of the battery pack remains within its specified temperature range, which is critical for preventing premature degradation and maintaining capacity over thousands of cycles.

Innovative Battery Cooling Designs for Enhanced Efficiency

Modern energy storage demands more than just basic cooling; it requires intelligent and dynamic thermal management. This has led to the development of Innovative battery cooling designs that significantly improve upon traditional concepts. Instead of constant-speed fans, new systems incorporate variable-speed blowers that modulate their output based on real-time temperature sensor data and operational load. Furthermore, the internal architecture of the battery pack itself is a key area of innovation. Engineers now design cell arrangements and housing structures that create optimized, non-obstructed pathways for airflow, minimizing pressure drop and ensuring that air reaches the centermost cells, which are often the most difficult to cool. These designs are fundamental to the reliability of integrated solutions like the SI Station, where performance cannot be compromised.

The Critical Role of Cooling Airflow Optimization for Batteries

Achieving uniform temperature distribution across hundreds or thousands of individual cells is a significant technical challenge. This is where the science of Cooling airflow optimization for batteries becomes indispensable. Engineers leverage powerful computational fluid dynamics (CFD) simulations to model how air moves through a battery pack before a single physical prototype is built. These simulations allow for the precise refinement of duct shapes, vent placements, and baffle locations to eliminate stagnant hot spots and ensure consistent cooling. Proper airflow optimization not only extends the operational life of the battery but also enhances its overall efficiency, as cells operating at their ideal temperature exhibit lower internal resistance. This meticulous engineering ensures that the entire battery system performs as a cohesive and reliable unit.

Battery Thermal Runaway Prevention through Advanced Cooling

Perhaps the most critical function of any battery thermal management system is safety, specifically Battery thermal runaway prevention. Thermal runaway is a dangerous chain reaction where an overheating cell releases its energy, causing adjacent cells to overheat and fail in a cascading effect. A well-designed air cooling system serves as a primary line of defense against this phenomenon. By having the capacity to rapidly increase airflow and evacuate a sudden buildup of heat—caused by an internal short, overcharging, or physical damage—the system can interrupt the chain reaction before it escalates. This rapid response capability is a non-negotiable safety feature in high-capacity energy storage solutions, providing the stability and peace of mind required for both industrial and residential applications.