The Future of Energy Storage: The Role of Advanced Cooling

As the demand for high-capacity energy storage continues to surge across commercial and industrial sectors, the technology underpinning these systems must evolve to ensure safety, efficiency, and longevity. A critical component in this evolution is the Liquid Cooling Battery Cabinet, a sophisticated solution designed to manage the thermal challenges inherent in high-density battery arrays. Unlike traditional cooling methods, liquid cooling provides a far more effective way to dissipate heat, maintaining optimal operating temperatures and unlocking the full potential of modern battery technology. This innovation is not just an improvement; it's a fundamental requirement for the next generation of reliable and powerful energy storage solutions.

Understanding Battery Cabinet Cooling Technology

At the heart of these advanced systems lies innovative Battery Cabinet Cooling Technology. Traditional air cooling systems often struggle to evenly and efficiently cool densely packed battery cells, leading to hot spots that can degrade battery health and pose safety risks. Liquid cooling, however, circulates a specialized coolant through a network of pipes or plates that are in direct or close contact with the battery modules. This method allows for a much higher rate of heat transfer, pulling thermal energy away from the cells with remarkable efficiency. The captured heat is then transported to a radiator or heat exchanger, where it is safely released into the ambient environment. This precise thermal management prevents overheating, minimizes temperature variations across the entire pack, and is a cornerstone of modern Liquid Cooled Battery Systems.

Key Advantages of Liquid Cooled Battery Systems

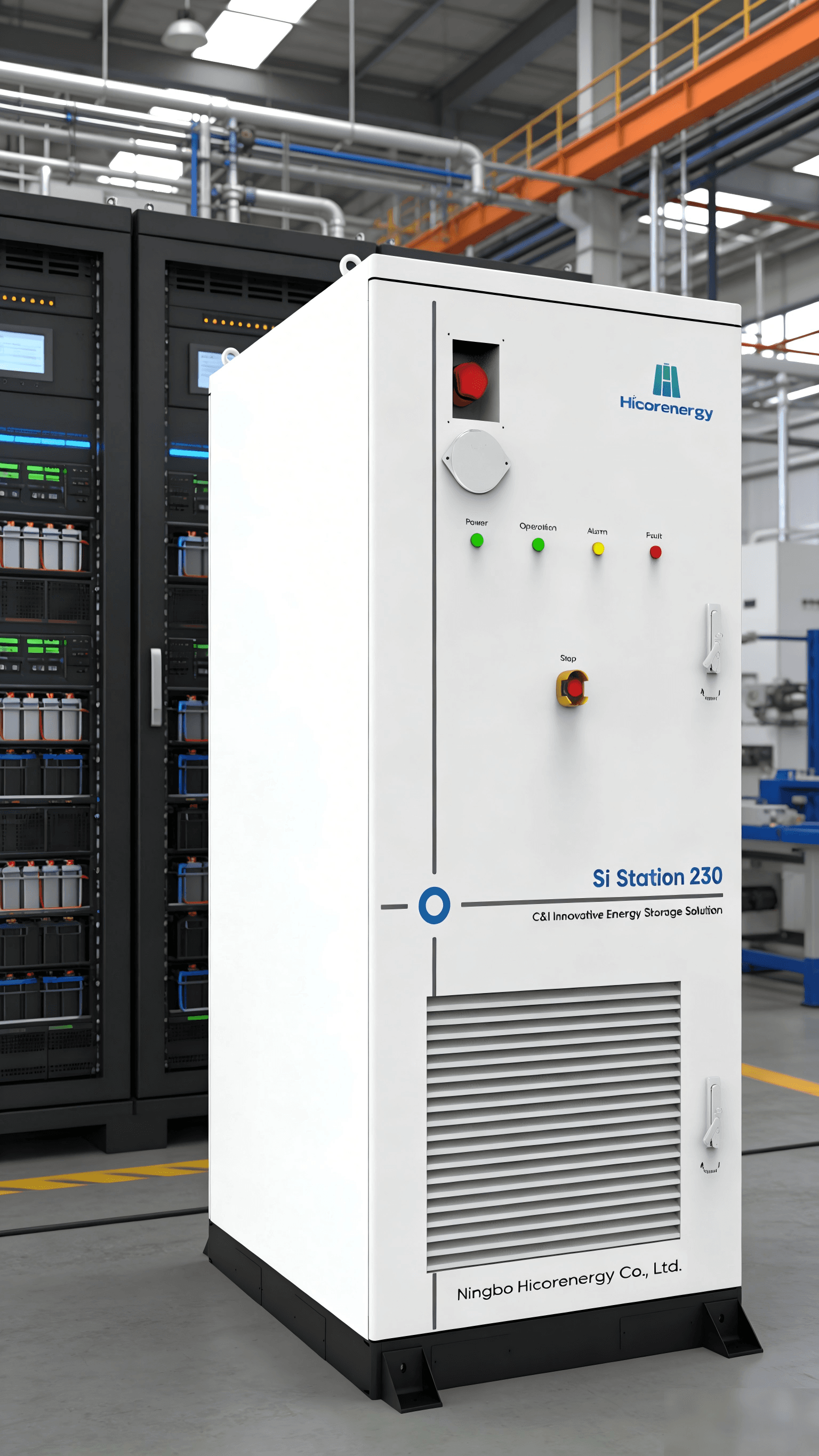

Embracing Liquid Cooled Battery Systems offers a multitude of benefits that are essential for mission-critical applications. The primary advantage is enhanced safety. By effectively preventing excessive heat buildup, the risk of thermal runaway—a dangerous and self-perpetuating heating cycle—is significantly reduced. Secondly, performance is dramatically improved. Batteries operate most efficiently within a specific temperature range, and liquid cooling ensures they remain within this optimal window, even under heavy charge or discharge cycles. This leads to higher energy output and consistent reliability. Finally, this superior thermal management extends the operational lifespan of the batteries, protecting the significant investment these systems represent. Products like the Si Station 230 and Si Station 186 from Ningbo Hicorenergy exemplify this leap forward, integrating robust design with advanced thermal controls to deliver efficiency and a greener future for commercial and industrial energy storage.

Applications and Industry Innovations

Leading-edge solutions like the Liquid Cooling Battery Cabinet are becoming indispensable across various industries. They are crucial for large-scale renewable energy projects, such as solar and wind farms, where they store vast amounts of power reliably. Data centers rely on them for uninterrupted power supplies, and the rapidly growing electric vehicle infrastructure depends on them for fast-charging stations. Companies are pushing the boundaries of what's possible, creating integrated solutions that are both powerful and resilient. The Si Station series, for example, is not just a battery unit but a complete energy solution with intuitive controls, safety features, and a durable casing designed for longevity in harsh environments. This commitment to innovation is paving the way for a more sustainable and electrified world, proving that advanced cooling is a key enabler of tomorrow's energy vision.