The Crucial Role of Thermal Management in Modern Energy Storage

As the world transitions towards renewable energy sources, the demand for high-capacity, high-performance energy storage systems has skyrocketed. At the heart of this revolution are advanced battery systems, which must operate efficiently and safely under demanding conditions. A critical component ensuring this reliability is the Liquid Cooling Battery Cabinet, a sophisticated enclosure designed to maintain optimal operating temperatures for battery modules. Proper thermal management is no longer a luxury but a necessity, directly impacting the lifespan, safety, and overall performance of the entire energy storage infrastructure. Without effective cooling, the promise of 24/7 power availability and grid independence would be severely compromised by the physical limitations of battery chemistry.

Advancements in Battery Cabinet Cooling Technology

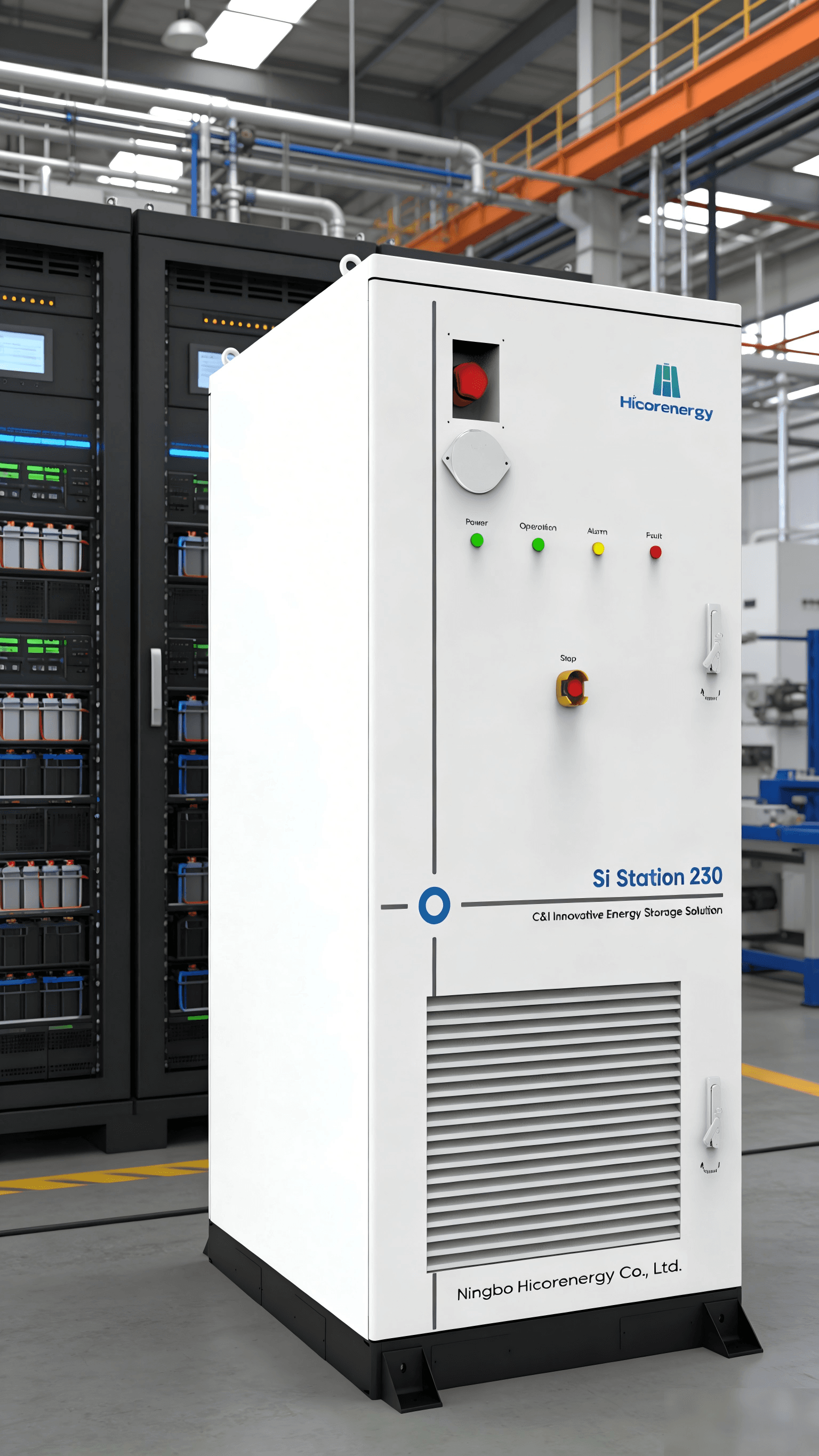

Historically, simpler air-cooling methods were sufficient for less demanding battery applications. However, as energy density and charge/discharge rates have increased, so has the amount of waste heat generated. This has driven the evolution of more robust thermal management solutions. Modern Battery Cabinet Cooling Technology has shifted significantly towards liquid-based solutions due to their superior thermal conductivity. Unlike air, liquid can absorb and transfer heat far more efficiently, allowing for precise temperature control across all cells within a module. This prevents the formation of hotspots, which are a primary cause of accelerated cell degradation and potential thermal runaway events. This technological leap is fundamental to enabling the high-performance characteristics seen in cutting-edge products like the Hicorenergy smart energy storage system, which promises durability and maximum efficiency.

Exploring the Mechanics of Liquid Cooled Battery Systems

Liquid Cooled Battery Systems operate on a principle of direct and efficient heat extraction. Inside a Liquid Cooling Battery Cabinet, a specialized, non-conductive coolant circulates through a network of channels or cold plates that are integrated closely with the battery modules. As the batteries charge and discharge, the coolant absorbs the generated heat and carries it away from the cells. This heated fluid is then pumped to a heat exchanger or radiator, where it releases the thermal energy into the ambient environment before being recirculated back to the batteries. This continuous cycle ensures that the batteries are kept within their ideal temperature range, typically between 20 to 30 degrees Celsius. This meticulous process allows for the densely packed, modular designs of modern systems, maximizing energy storage capacity in a minimal footprint while ensuring safe and consistent operation.

The Tangible Benefits of Superior Cooling

Adopting advanced thermal management solutions like Liquid Cooled Battery Systems brings a host of tangible benefits. The most significant advantage is an extended battery lifespan. By preventing exposure to extreme temperatures, cell degradation is slowed dramatically, protecting the owner's investment and ensuring long-term reliability. Secondly, performance is substantially boosted. With effective cooling, systems can handle faster charging and discharging cycles without risk of overheating, making them more responsive and versatile for both residential and commercial applications. Safety is also greatly enhanced, as maintaining stable temperatures is the first line of defense against thermal runaway. This advanced Battery Cabinet Cooling Technology is a key enabler for achieving the kind of resilience and intelligent energy management that defines the future of sustainable living.