In the rapidly evolving landscape of energy storage, the efficiency and longevity of battery systems are paramount. A critical component ensuring optimal performance, especially in high-demand Commercial and Industrial (C&I) applications, is the Liquid Cooling Battery Cabinet. This sophisticated enclosure is designed not just to house battery modules, but to actively manage their thermal environment, which is crucial for safety, reliability, and extending the operational life of the entire system. As energy density in battery packs increases, traditional air cooling methods are becoming insufficient, paving the way for more advanced solutions that can handle significant heat loads efficiently.

The Superiority of Liquid Cooled Battery Systems

At the heart of this innovation are Liquid Cooled Battery Systems. Unlike air cooling, which relies on circulating air to dissipate heat, liquid cooling uses a specialized coolant that flows through pipes or plates integrated within the battery cabinet. This fluid has a much higher heat capacity than air, allowing it to absorb and transport heat away from the battery cells far more effectively. The result is superior temperature uniformity across all cells, preventing dangerous hotspots and ensuring each cell operates within its ideal temperature range. This precise thermal control not only boosts performance and allows for faster charging and discharging rates but also significantly slows down battery degradation, maximizing the return on investment for large-scale energy storage projects.

Innovations in Battery Cabinet Cooling Technology

The advancement of Battery Cabinet Cooling Technology is a direct response to the growing demands of the renewable energy sector and grid stabilization efforts. Modern energy storage solutions are expected to be compact, powerful, and capable of operating in diverse and often harsh environmental conditions. Liquid cooling technology meets these challenges head-on. It allows for a more compact system design because it removes heat more efficiently in a smaller volume. This makes it possible to stack battery modules closer together, increasing the overall energy density of the installation. Furthermore, for outdoor units like Hicorenery's Si Station series, a robust thermal management system is essential to protect the batteries from extreme ambient temperatures, ensuring consistent and reliable operation year-round.

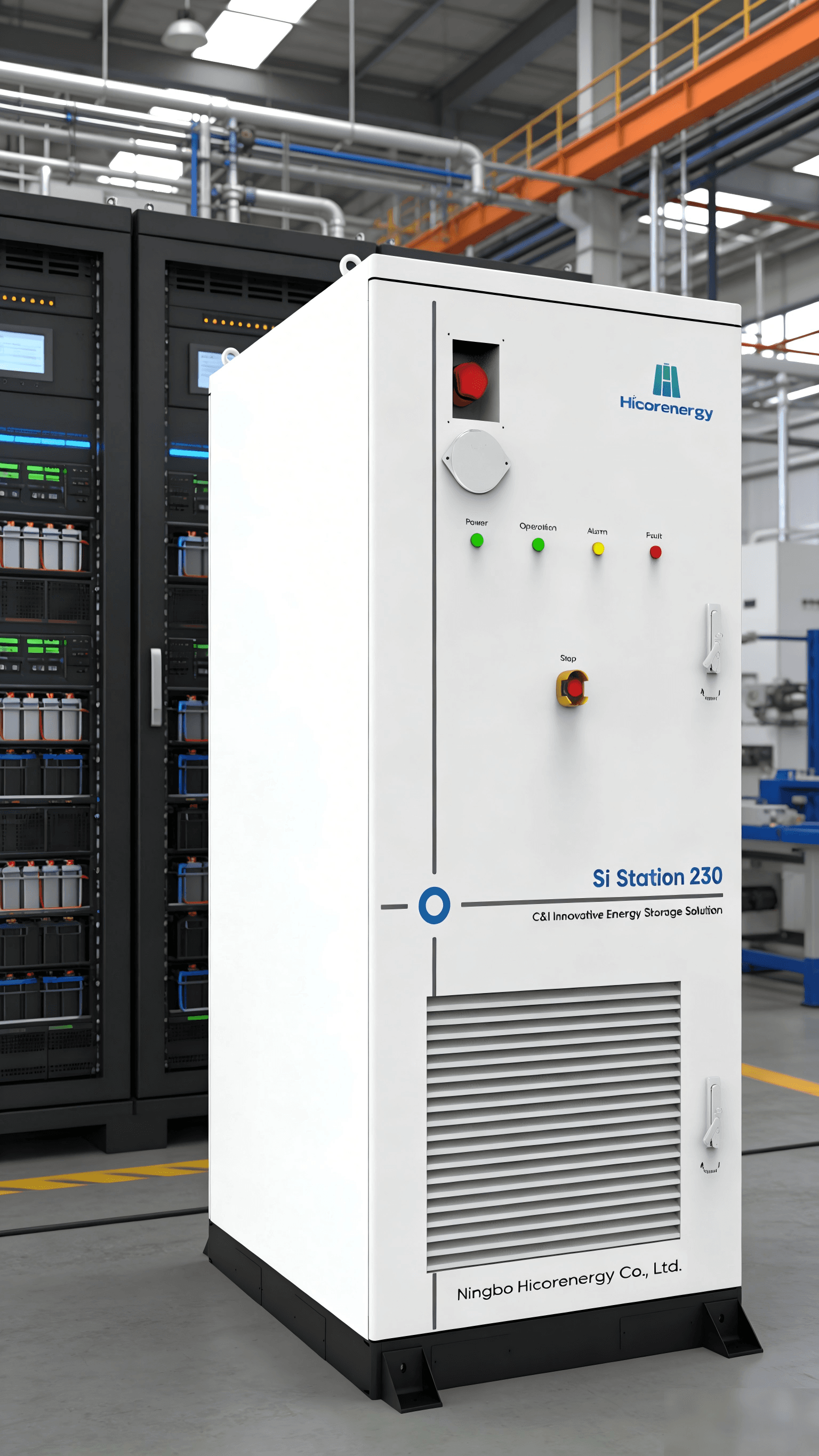

The Si Station: Embodying Advanced Thermal Management

A prime example of a system built for these modern challenges is the Si Station series from Ningbo Hicorenery Co., Ltd. While designed for robust outdoor C&I use, the Si Station 230 and Si Station 186 showcase the principles of advanced energy management where superior cooling is a prerequisite. To achieve the resilience, high performance, and streamlined architecture these units offer, an effective thermal solution like a Liquid Cooling Battery Cabinet is fundamental. The ability of these stations to support grid stability and provide reliable backup power is directly linked to the health and readiness of their internal battery systems, which can only be guaranteed through state-of-the-art Battery Cabinet Cooling Technology. This integrated design approach ensures minimal maintenance, ease of installation, and a reduced carbon footprint, aligning perfectly with green energy initiatives.

The Future of Energy Storage is Efficiently Cooled

Ultimately, the move towards Liquid Cooled Battery Systems is not just a trend but a foundational shift in how we approach energy storage. The reliability and efficiency of these systems are critical for the successful integration of renewable energy sources into our power grids. By providing precise and powerful thermal control, this technology ensures that energy storage solutions can meet the rigorous demands of today's energy landscape. As we continue to push the boundaries of battery capacity and performance, advanced cooling will remain a cornerstone of safe, long-lasting, and sustainable energy management for a smarter future.