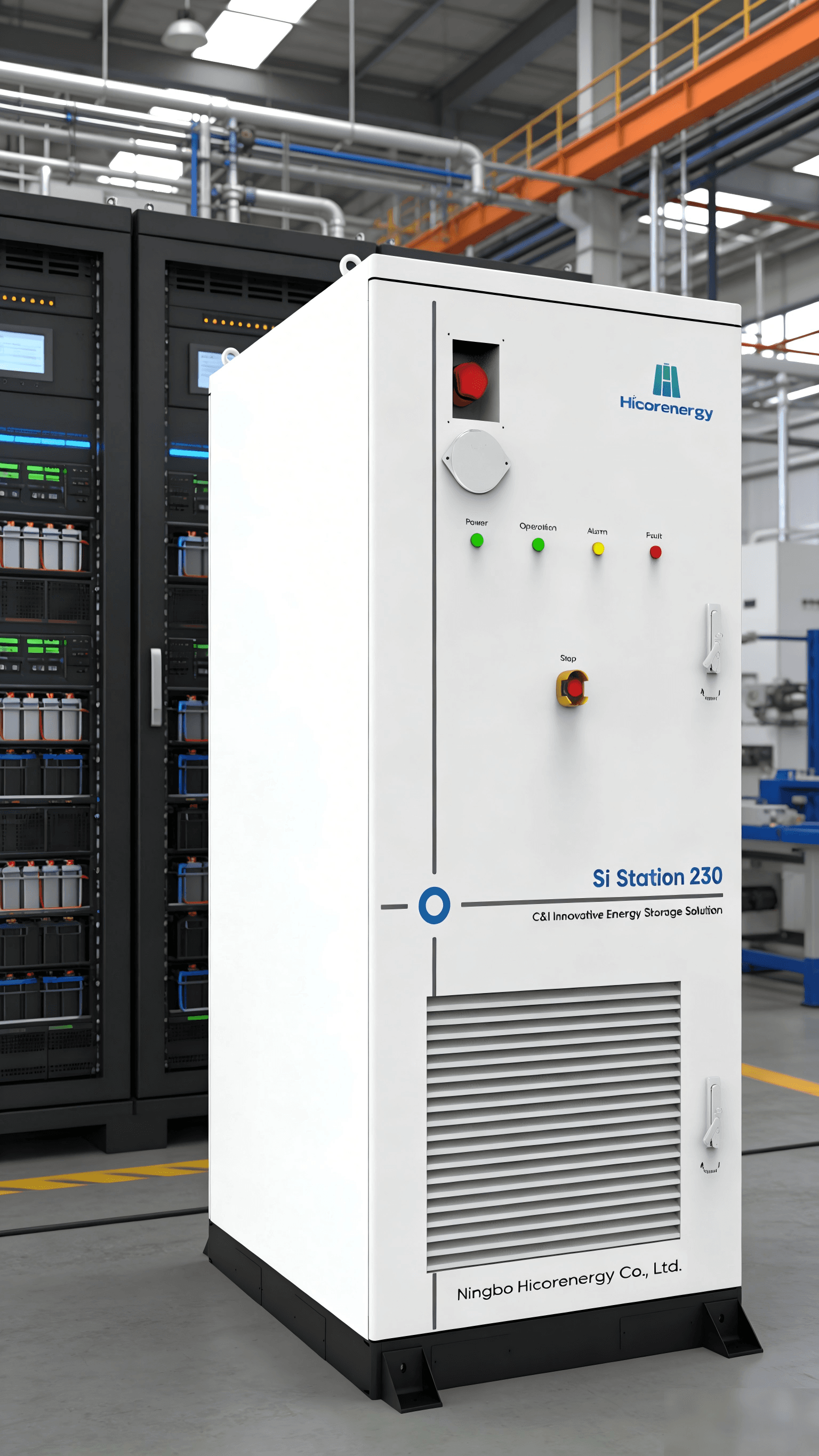

The efficiency and longevity of modern energy storage solutions are fundamentally tied to their thermal management capabilities. An advanced Air Cooling Battery System is a cornerstone of this technology, providing a reliable and cost-effective method for maintaining optimal operating temperatures. For large-scale applications, such as the HicorEnergy SI Station 230 and SI Station 186, managing heat is not just a matter of performance but a critical safety requirement. These systems are engineered to dissipate the significant thermal energy generated during high-power charge and discharge cycles, ensuring the stability and extended life of the entire energy storage infrastructure.

The efficiency and longevity of modern energy storage solutions are fundamentally tied to their thermal management capabilities. An advanced Air Cooling Battery System is a cornerstone of this technology, providing a reliable and cost-effective method for maintaining optimal operating temperatures. For large-scale applications, such as the HicorEnergy SI Station 230 and SI Station 186, managing heat is not just a matter of performance but a critical safety requirement. These systems are engineered to dissipate the significant thermal energy generated during high-power charge and discharge cycles, ensuring the stability and extended life of the entire energy storage infrastructure.

The Critical Role of Cooling Systems for Lithium-Ion Batteries

At the heart of today's energy storage are lithium-ion cells, which are sensitive to temperature fluctuations. Effective Cooling systems for lithium ion batteries are non-negotiable for safe and efficient operation. During their electrochemical processes, batteries naturally generate heat. If this heat is not effectively removed, cell temperatures can rise, leading to accelerated degradation, reduced capacity, and a shorter operational lifespan. In more severe cases, excessive heat can trigger hazardous conditions. Therefore, the design of the thermal management system directly impacts the return on investment and the overall safety profile of the battery system, making it a primary consideration for system integrators and operators.

Exploring Innovative Battery Cooling Designs

As battery technology evolves, so too must the methods used to cool it. We are seeing a shift towards more Innovative battery cooling designs that employ sophisticated engineering principles. Rather than simply using fans for ventilation, advanced systems utilize precisely engineered air channels, plenums, and baffles to guide airflow directly to the hottest parts of the battery modules. This approach ensures uniform temperature distribution and prevents the formation of localized hot spots, which are a common point of failure. The meticulous engineering found in high-capacity storage units, such as those developed by Ningbo Hicorenergy Co., Ltd., exemplifies this trend, where every component of the thermal system is optimized for maximum heat dissipation and energy efficiency.

A Proactive Approach to Battery Thermal Runaway Prevention

One of the most critical safety functions of a cooling system is Battery thermal runaway prevention. This dangerous phenomenon occurs when a cell overheats to the point of initiating an uncontrollable, self-sustaining exothermic reaction, which can propagate to adjacent cells and lead to catastrophic system failure. An intelligent Air Cooling Battery System acts as a crucial first line of defense. By continuously monitoring cell temperatures and dynamically adjusting airflow, the system can proactively manage heat and keep temperatures well below the threshold for thermal runaway. This active management, coupled with advanced battery monitoring systems (BMS), provides the robust safety and reliability demanded in modern industrial and grid-scale energy storage applications.

The Future of Thermal Management: Cooling Airflow Optimization for Batteries

Achieving peak performance from an air-cooled system depends heavily on Cooling airflow optimization for batteries. This involves more than just powerful fans; it requires a holistic design approach that considers the aerodynamic path through the battery racks. Engineers use tools like computational fluid dynamics (CFD) to model and refine air pathways, minimizing pressure drops and ensuring that every cell receives adequate cooling. This level of optimization allows an Air Cooling Battery System to perform effectively even under high ambient temperatures and demanding load profiles. Such Innovative battery cooling designs ensure that systems like the HicorEnergy SI Stations can deliver on their promise of resilient, high-efficiency energy management while contributing to a safer and more sustainable energy future.