The performance and longevity of modern battery energy storage systems (BESS) are fundamentally linked to their thermal management. An advanced Air Cooling Battery System is a critical component, designed to maintain lithium-ion cells within their optimal temperature range, ensuring efficiency, safety, and a long operational life. As the energy density of batteries increases, so does the heat they generate during charge and discharge cycles. Without effective heat dissipation, batteries can suffer from accelerated degradation, reduced capacity, and significant safety risks, making the engineering behind their cooling mechanisms more important than ever.

The performance and longevity of modern battery energy storage systems (BESS) are fundamentally linked to their thermal management. An advanced Air Cooling Battery System is a critical component, designed to maintain lithium-ion cells within their optimal temperature range, ensuring efficiency, safety, and a long operational life. As the energy density of batteries increases, so does the heat they generate during charge and discharge cycles. Without effective heat dissipation, batteries can suffer from accelerated degradation, reduced capacity, and significant safety risks, making the engineering behind their cooling mechanisms more important than ever.

Exploring Advanced Cooling Systems for Lithium Ion Batteries

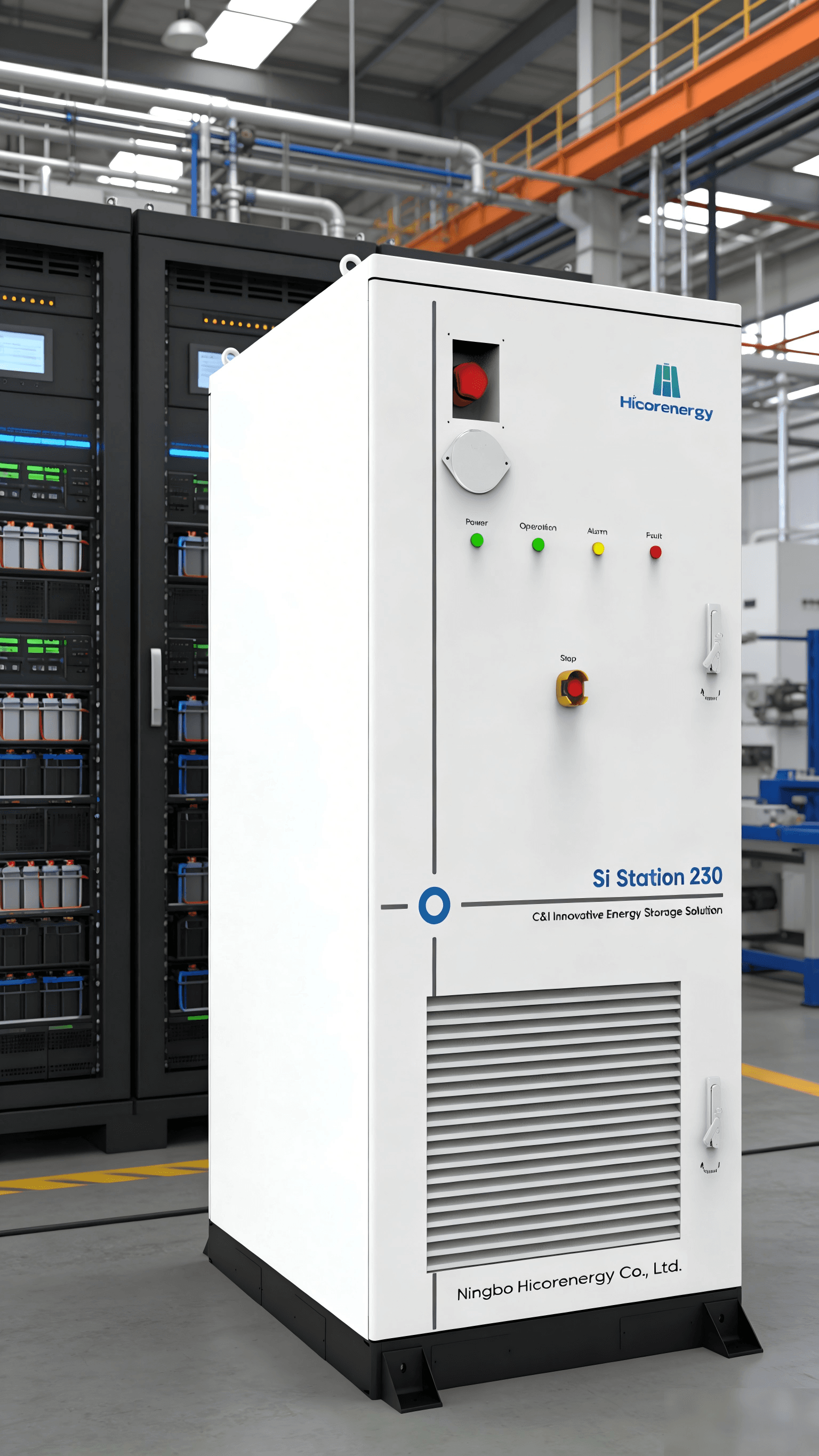

When engineering a BESS, one of the primary decisions revolves around the choice of thermal management. The various cooling systems for lithium ion batteries generally fall into two categories: air and liquid cooling. While liquid cooling offers high thermal conductivity, an Air Cooling Battery System provides distinct advantages in terms of simplicity, lower cost, reduced maintenance, and lighter weight. These systems use fans to force ambient or conditioned air through channels and over the surfaces of battery modules. In sophisticated solutions like the Hicorenergy SI Station 230 and SI Station 186, this approach is refined to a high degree, ensuring reliable performance across diverse operating environments without the complexity and potential leakage risks associated with liquid coolants.

The Science of Airflow Optimization and Design

Effective air cooling is not merely about blowing air at batteries; it is a science of precision and control. Innovative battery cooling designs focus on creating uniform temperature distribution across the entire battery pack. This prevents a few cells from becoming hotter than others, which can lead to imbalances and premature failure. Achieving this requires meticulous Cooling airflow optimization for batteries, often modeled using advanced computational fluid dynamics (CFD) simulations. Engineers can optimize the design of air plenums, the placement and speed of fans, and the geometry of air channels between cells. This level of advanced engineering, integral to the design of Hicorenergy's SI Stations, ensures that every cell is cooled effectively, maximizing the system's overall performance and lifespan. Such innovative battery cooling designs are a hallmark of high-quality energy storage products.

A Proactive Approach to Battery Thermal Runaway Prevention

A primary safety concern for any lithium-ion BESS is the risk of thermal runaway, a dangerous chain reaction where an overheating cell causes adjacent cells to overheat, potentially leading to catastrophic failure. Effective Battery thermal runaway prevention is therefore a non-negotiable aspect of system design. A well-engineered Air Cooling Battery System plays a crucial role in this preventative strategy. By actively removing excess heat, the system keeps cell temperatures well below the threshold where thermal runaway can initiate. Furthermore, the strategic airflow can help isolate a failing cell thermally and vent any gases safely, preventing propagation. This focus on Battery thermal runaway prevention ensures that systems are not only high-performing but also fundamentally safe and reliable for both residential and commercial applications.

In conclusion, the sophisticated engineering behind modern air cooling is foundational to the success of today's energy storage solutions. Through Cooling airflow optimization for batteries and intelligent design, these systems deliver exceptional thermal management. Products like the Hicorenergy SI Station 230 and SI Station 186 showcase how these principles are applied to create energy solutions that are not only powerful and efficient but also inherently safe and durable. The future of sustainable energy relies on this commitment to technical excellence in every component, especially the critical cooling systems that protect the heart of the BESS.