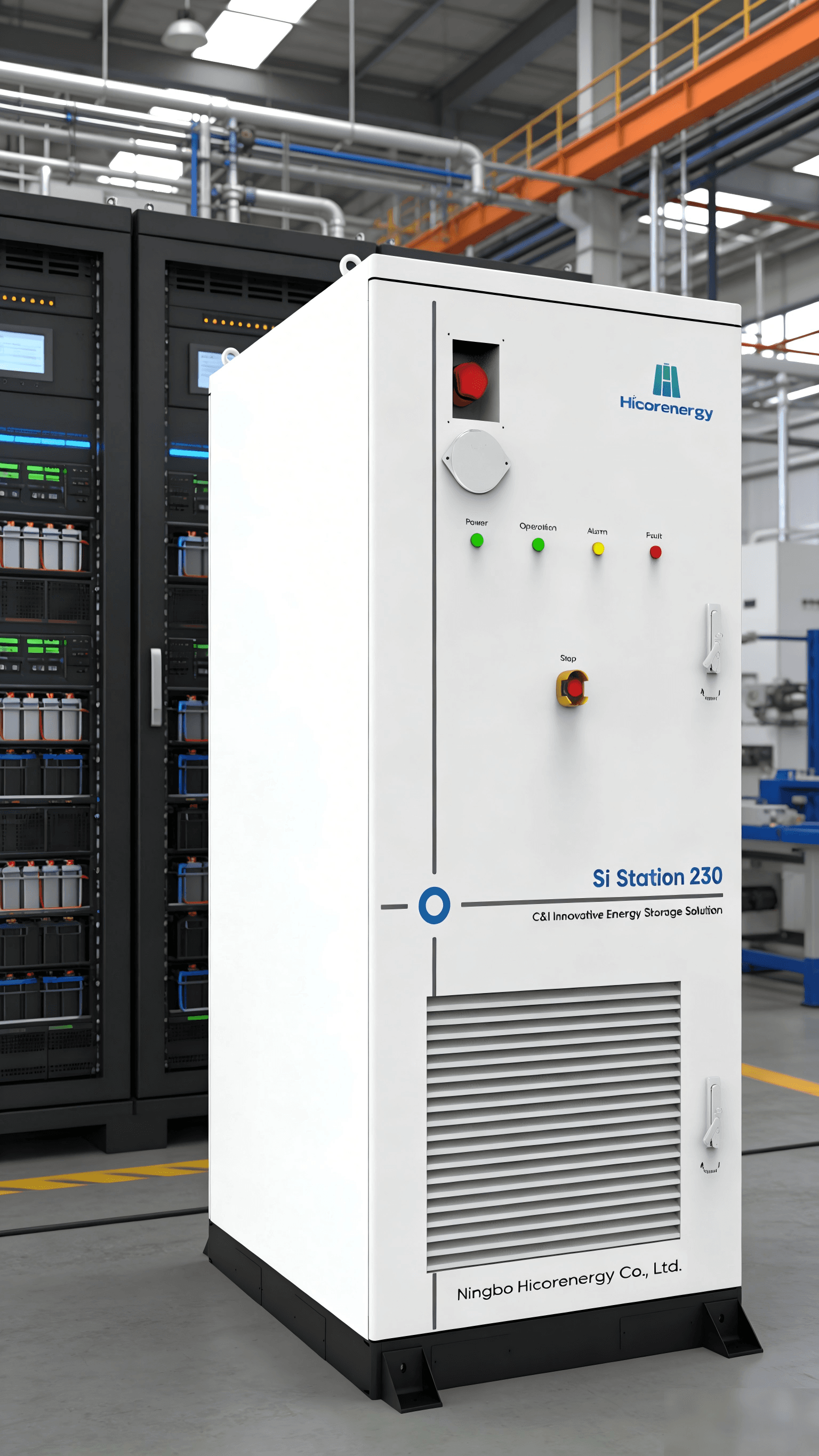

As the world transitions towards renewable energy sources like solar and wind, the need for robust and efficient energy storage systems has become more critical than ever. Powerful solutions like the HiCorenergy Si Station 230 are essential for capturing and storing this energy, ensuring a stable power supply. However, managing the immense power within these units presents a significant thermal challenge. This is where the advanced design of a Liquid Cooling Battery Cabinet becomes not just a feature, but a fundamental necessity for performance and longevity, representing the pinnacle of modern Cooling Technology for Batteries.

As the world transitions towards renewable energy sources like solar and wind, the need for robust and efficient energy storage systems has become more critical than ever. Powerful solutions like the HiCorenergy Si Station 230 are essential for capturing and storing this energy, ensuring a stable power supply. However, managing the immense power within these units presents a significant thermal challenge. This is where the advanced design of a Liquid Cooling Battery Cabinet becomes not just a feature, but a fundamental necessity for performance and longevity, representing the pinnacle of modern Cooling Technology for Batteries.

The Hidden Danger: Overheating in High-Capacity Batteries

High-performance battery systems, whether on a solar farm or in a wind power facility, are constantly charging and discharging massive amounts of energy. This intense activity generates a substantial amount of heat. If left unmanaged, this heat can lead to a cascade of negative effects. Elevated temperatures accelerate battery degradation, significantly shortening their operational lifespan and reducing their overall capacity. More critically, excessive heat poses a serious safety risk, potentially leading to thermal runaway—a dangerous and irreversible chemical reaction. Therefore, implementing effective Battery Safety Solutions is non-negotiable, and thermal management is the first line of defense. Traditional air cooling methods often fall short in these demanding, high-density applications, struggling to dissipate heat quickly and evenly enough to protect the sensitive cells within.

The Solution: The Efficiency of Liquid Cooling Technology

A Liquid Cooling Battery Cabinet addresses these challenges with superior efficiency and precision. Unlike air, liquid is a far more effective medium for heat transfer. This system works by circulating a specialized dielectric coolant through channels or plates that are in direct or close contact with the battery modules. The fluid absorbs heat directly from the cells and carries it away to a radiator or heat exchanger, where it is safely dissipated. This process allows for precise temperature control across the entire battery pack, ensuring all cells operate within their optimal temperature range. The implementation of advanced Liquid Cooling Technology means that systems like the Si Station 230 can operate at peak performance for longer periods without the risk of overheating, unlocking their full potential.

Building a Safer and More Sustainable Energy Future

The benefits of this advanced approach extend beyond just performance. By maintaining optimal temperatures, liquid cooling directly contributes to Sustainable Battery Cooling. It extends the life of the batteries, reducing the frequency of replacements and minimizing waste. This longevity also improves the return on investment for large-scale energy projects. Furthermore, the enhanced safety provided by a robust cooling system builds trust and reliability in green energy infrastructure. This commitment to superior thermal management and Battery Safety Solutions is a principle that has been proven in other demanding fields, such as the EV Battery Cooling sector, where performance and safety are paramount. The use of Liquid Cooling Technology ensures that cornerstone products of our future smart grid can function reliably, paving the way for a more secure and sustainable energy landscape for generations to come.

In conclusion, as we increasingly depend on high-capacity energy storage to support our renewable goals, the technology inside these units must evolve. The move from simple air cooling to a sophisticated Liquid Cooling Battery Cabinet is a crucial step in this evolution. It is a testament to the engineering required to maximize efficiency, ensure safety, and promote Sustainable Battery Cooling. For innovative systems designed to manage the power of the sun and wind, this advanced thermal management is what guarantees a reliable and enduring contribution to a cleaner planet.